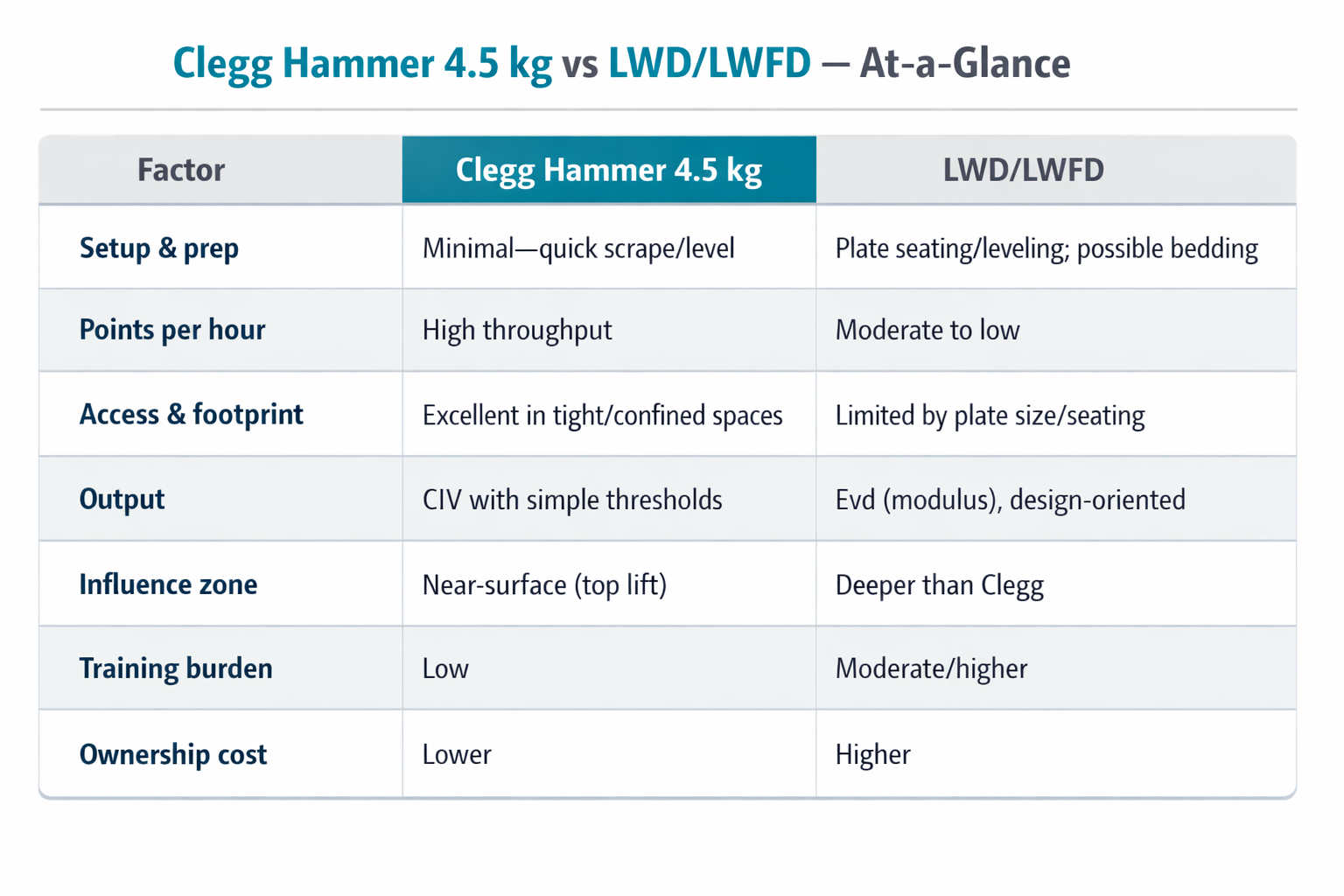

Clegg Hammer 4.5 kg vs. Lightweight Falling Deflectometer (LWFD): Why Speed and Simplicity Win

If your crews live on tight deadlines and tighter job sites, the Clegg Hammer 4.5 kg is the smarter choice. It delivers fast, actionable compaction control with simple pass/fail targets, minimal setup, and true one-person mobility—exactly what field teams need to keep production moving. LWDs have their place, but when the goal is throughput and clarity on everyday earthworks, Clegg wins where it matters.

What Each Tool Delivers

Clegg 4.5 kg: Measures near-surface impact response to produce CIV (Clegg Impact Value) for quick compaction/strength checks.

LWD/LWFD: Measures surface deflection under a load plate to calculate a dynamic stiffness modulus (Evd) for design-leaning evaluations.

Why Teams Choose the Clegg 4.5 kg

Faster workflow: Minimal surface prep, no plate bedding, and streamlined drops mean more test points per hour and less waiting on results.

Simpler pass/fail: Clear CIV thresholds are easy for field crews to learn and apply—no modulus calculations or complex conversions required.

Go-anywhere portability: Light, compact, and ideal for trenches, edges, slopes, and confined areas where an LWD plate can’t seat properly.

Lower total cost of ownership: Fewer components, faster training, and reduced maintenance/calibration overhead make budgeting easier.

Safer one-person use: Less weight, fewer parts, and less fiddly setup reduce fatigue and errors during long field days.

Where the LWD Still Makes Sense (Fair and Balanced)

Your spec mandates modulus (Evd) for acceptance.

You’re tuning structural stiffness for mechanistic design or evaluating thicker layers beyond 8 inches (200MM).

You need to correlate to FWD/static plate tests within a specific agency workflow.

Real-World Scenarios Where Clegg Shines

Utility trench backfill: Rapid acceptance at every lift without disrupting traffic or production.

Edge-of-pavement and around structures: Validate compaction right up against curbs, manholes, pipes, and walls.

Small to mid-size earthworks: Keep grading, pad construction, and patching moving with fast, repeatable checks.

Sports/turf and topsoil layers: Leverage familiar CIV targets for consistent surface hardness and performance.

A Simple, High-Confidence QA Workflow

Prep the spot (quickly level/clean the surface).

Perform standardized drops: discard the seating blow and record subsequent CIV values.

Compare to project targets: use clear pass/fail thresholds or a local CIV-to-CBR/compaction correlation.

Document results: log readings with location and moisture notes for an easy audit trail.

Results Stakeholders Understand

Clear thresholds that inspectors, owners, and crews can align on.

High test density to reduce risk and rework.

Consistent, repeatable readings that support defensible acceptance decisions.

If you need a stiffness modulus for design or mandated Evd specs, use an LWD. For everything else—fast-moving acceptance, constrained access, simple training, and cost-effective quality control—the Clegg Hammer 4.5 kg is the practical winner. It’s the tool that keeps crews working, not waiting.

Want to see how the Clegg Hammer 4.5 kg fits your quality control program? Reach out to us and let’s streamline your compaction testing and keep your projects on schedule.